Creating bespoke designs focused upon practicality in a range of materials

We offer thermoforming and vacuum forming

We’ve been working with clients from a wide range of sectors since 1982, and over the course of more than four decades we’ve developed a state of the art facility featuring cutting edge technology utilised by time-served engineers and technicians. Our team can boast more than 100 years’ worth of combined experience and, even more importantly, they all work on the basis of the ASH Plastics ethos of quality, excellence and value for money.

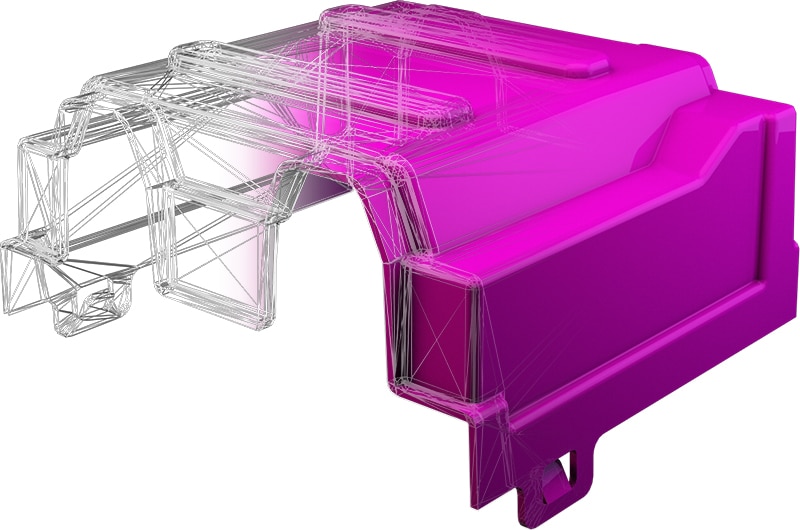

Thermoforming design process

As specialists in delivering solutions utilising plastics such as acrylic, polycarbonate, polypropylene, polyethylene, ABS and HIPS we make use of a wide range of different techniques, from laser cutting to line bending. One of the major techniques utilised when working with plastics in order to deliver precision results is thermoforming and, in particular, vacuum forming.

In simple terms, thermoforming involves heating sheets of plastic until they reach a temperature at which they are sufficiently pliable. Once the plastic has reached the right temperature it can be placed over a mould of the desired shape and pressed into place.

Vacuum forming design

The mould in question can be male or female, depending upon the shape being moulded, with a male mould being a ‘positive’ shape which presses up into the sheet of plastic and a female mould being negative in nature, forming a space into which the plastic sheet presses down.

In basic thermoforming the plastic sheet is pressed into place and left to cool and harden.

Vacuum forming involves a similar process except that, once the plastic has been placed over or into the mould the air is vacuumed out, sucking the plastic firmly against the mould and creating the closest possible fit.

Using the latest and most innovative materials

Our vacuum and thermoforming services can be combined with the other technology we use to create bespoke solutions, and our 20,000 sq. ft. facility boasts the scale needed to deliver bulk orders of items at speed and for the best possible price.

We work in close partnership with every client, developing detailed CAD designs from the initial brief and then manufacturing and assembling the finished product in-house.

Contact Our Experts

If you’d like to learn more about the end-to-end one stop service we could provide for your company please get in touch. Our experts are ready and waiting to answer any questions and explain exactly what we could do to turn your ideas into a reality.

Call us or send an email and we’ll start the process of delivering the solutions you’re looking for.

Tel: +44(0)1902 450 300

Email: hello@ashplastics.co.uk

Frequently Asked Questions

Mechanical thermoforming is a plastic forming process, completed by vacuum or pressure forming, which shapes a heated thermoplastic sheet with the use of a mould.

A mould is designed in the specific shape of the desired product or part, before a plastic sheet is secured on top of it. The sheet is then heated, and pressed or suctioned onto the mould. The plastic sheet subsequently takes the shape of the mould.

Vacuum forming is a method of thermoforming that utilises a suction motion to mould the heated plastic sheet around the mould so that it can be shaped. Vacuum forming requires one mould to produce the part, unlike pressure moulding which requires two (plastic is shaped between two moulds which are pressed down onto one another).

There are many vacuum forming advantages; vacuum forming has a fast turnaround time and great flexibility in the shapes it can produce, since the mould can easily be modified or replaced. It is a relatively affordable process, particularly suitable for small to medium product batches.

Shapes are generally consistent across batches, and scrap thermoplastic can easily be recycled, helping to reduce manufacturing costs further.

Some vacuum forming disadvantages include: vacuum forming is more suited to producing simple shapes; deep draw is difficult to perform with vacuum cleaning, and thick plastics have to be carefully handled or are incompatible with this process.

Individual parts or products are produced at a time, rather than being a linear process; the mould will affect the outcome of the product, making it necessary that the mould is consistent across a batch.

Thermoforming polymers refer to types of plastics that can be continually heated and formed; when heated, they return to their original state, and can be formed to produce a new shape without turning brittle. Thermoforming plastics can be recycled because of this.

Vacuum forming materials include:

- Acrylonitrile butadiene styrene (ABS); this material is hard and rigid with good weather resistance, suitable for outdoor applications

- Acrylic Perspex (PMMA); PMMA has good strength but can be brittle

- Co-polyester (PETG); it is easy to form, with good strength, and can be sterilised for medical or food applications

- Polystyrene (HIPS); this material forms well with little shrinkage, and is suitable for the production of low-cost items

- Polycarbonate (PC/ LEXAN/ MAKROLON); this plastic is hard and rigid, with high strength and good fire resistance

- Polypropylene (PP); it is difficult to form, however is very flexible with good strength

- Polyethylene (HDPE); high density polyethylene is hard to form with a high shrinkage rate, but has very good strength and can be used for a variety of applications

Thermoforming plastics can be recycled, and should be recycled; because they can easily be reheated and reformed, thermoforming plastics can be recycled into new shapes and purposes. This reduces waste, and can ease the demand on the environment.

Thermoforming and thermosetting plastics are essentially opposites. Thermosetting polymers are brittle and can only be heated and formed once, whereas thermoforming polymers can be repeatedly heated and formed without affecting the integrity of the plastic.

Thermoforming examples can be seen in food containers and similar types of plastic packaging, as well as plastic signs and stands. Vacuum forming examples likewise include thin-walled plastic shapes such as desktop devices or dental retainers.