Laser Cutting & Engraving

Home » Plastic Forming & Fabrication Services » Machining » Laser Cutting & Engraving

Laser Cutting and Engraving: A Precision Tool for Plastic POS Displays

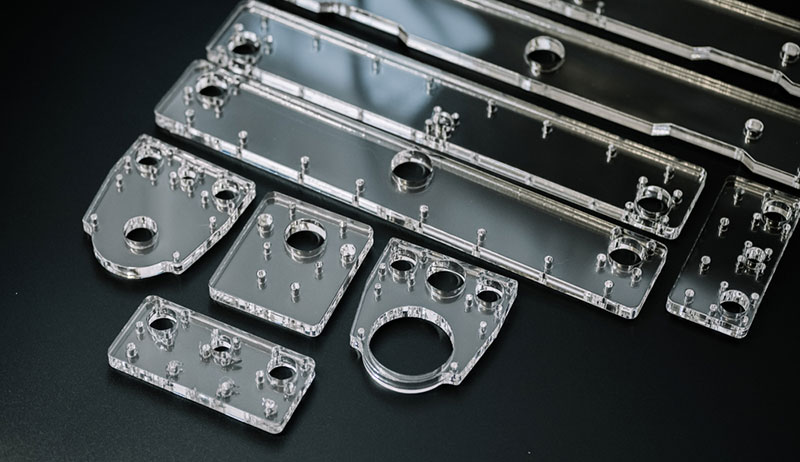

Laser cutting and engraving have revolutionized the manufacturing of point of sale (POS) displays, offering unparalleled precision, speed, and versatility. By utilizing laser technology, manufacturers can create intricate designs, complex shapes, and high-quality finishes on a variety of plastic materials.

Advantages of Laser Cutting and Engraving for POS Displays

- Precision and Accuracy: Laser cutting and engraving provide exceptional precision and accuracy, allowing for intricate details and complex patterns to be cut or engraved with minimal error.

- Versatility: Lasers can cut and engrave a wide range of plastic materials, including acrylic, polycarbonate, PET, and PVC. This versatility enables manufacturers to create displays that meet various aesthetic and functional requirements.

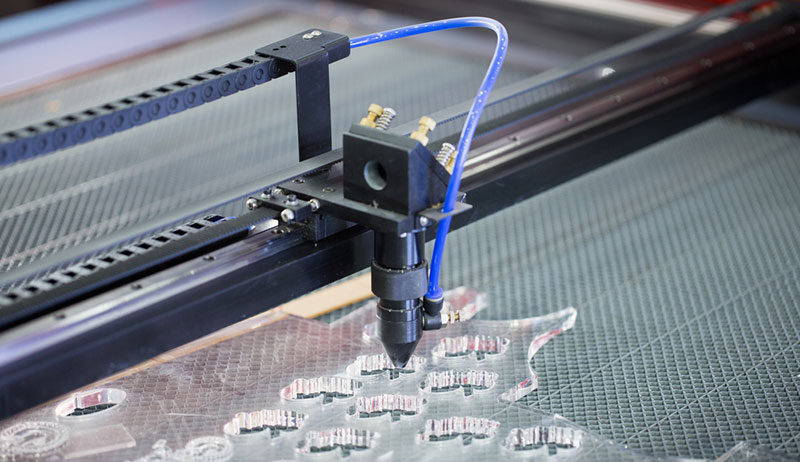

- Speed: Laser technology offers high-speed cutting and engraving, reducing production time and increasing efficiency.

- Non-Contact Processing: Laser cutting and engraving are non-contact processes, eliminating the need for physical tools or dies. This reduces the risk of damage to the material and ensures a clean, burr-free finish.

- Flexibility: Laser systems can be easily programmed to handle different designs and sizes, making them highly flexible and adaptable to changing market demands.

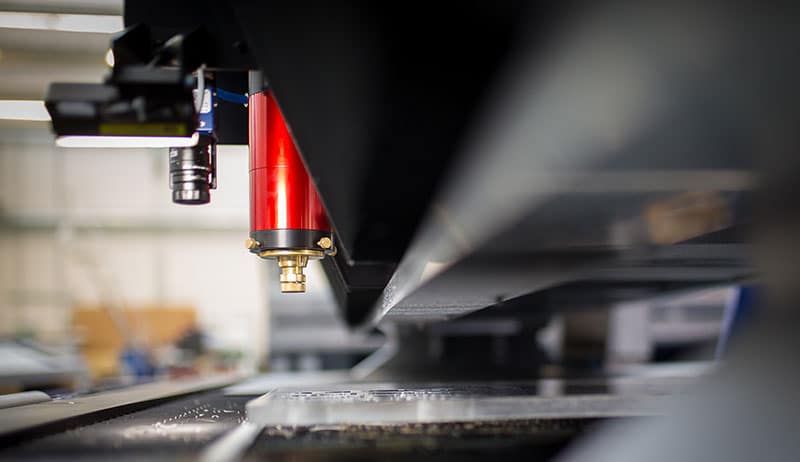

The Trotec Speedy 400: A Powerful Tool for POS Display Manufacturing

The Trotec Speedy 400 is a high-performance laser cutter and engraver that is ideal for manufacturing POS displays. This versatile machine offers a number of advantages, including:

- High Power: The Speedy 400 is equipped with a powerful laser source, allowing it to cut and engrave thick plastic materials efficiently.

- Large Format: The machine’s large format working area accommodates various display sizes, from small tabletop displays to large-scale signage.

- Precision Optics: The Speedy 400 features precision optics that ensure accurate and detailed cutting and engraving.

- Intuitive Software: The machine is controlled by easy-to-use software that simplifies design creation and job setup.

- Reliability: The Speedy 400 is known for its reliability and durability, ensuring long-term performance and minimal downtime.

By utilizing the Trotec Speedy 400 and other advanced laser cutting and engraving technologies, manufacturers can create visually stunning and functional POS displays that effectively showcase products and attract customers. The precision, speed, and versatility offered by laser technology have made it an indispensable tool for the modern POS display industry

Get in touch

We work with some of the biggest retail brands in the UK and many smaller independent retailers and businesses and we are ready to take on the next big industry challenge, that might just be your challenge too! Why not get in touch with us today.