Thermoforming is a versatile process. It shapes plastic into a variety of forms. At Ash Plastics, we often get questions about the different thermoforming techniques. This FAQ aims to clarify the various methods – line bending, dome blowing, vacuum forming, and drape forming – and answer your common queries.

General Thermoforming Questions:

Q: What is thermoforming?

A: Thermoforming is a manufacturing process. Plastic sheets are heated until pliable. Then shaped over a mold. Once cooled, the plastic retains the desired shape.

Q: What are the advantages of thermoforming?

A: Thermoforming offers several benefits:

- Cost-effective for large runs: Ideal for producing large quantities of identical parts.

- Design flexibility: Can create complex shapes and intricate details.

- Lightweight: Thermoformed parts are often lighter than those made from other materials.

- Durable: Offers good impact resistance and can be formulated for UV resistance.

- Variety of materials: Works with a wide range of thermoplastics.

Q: What types of plastics are used in thermoforming?

A: Common thermoplastics used in thermoforming include:

- ABS: Good balance of toughness and cost.

- Acrylic: Excellent optical clarity and weather resistance.

- Polycarbonate: High impact resistance and heat resistance.

- PVC: Versatile and cost-effective.

- PETG: Good clarity and food-safe.

Line Bending:

Q: What is line bending?

A: Line bending, also known as strip heating, involves heating a narrow strip of plastic sheet until it’s pliable, then bending it to a desired angle. It’s used to create angles and bends in signs, displays, and furniture.

Q: What are the limitations of line bending?

A: Line bending is best suited for creating simple bends and angles. It’s not ideal for complex curves or shapes.

Dome Blowing:

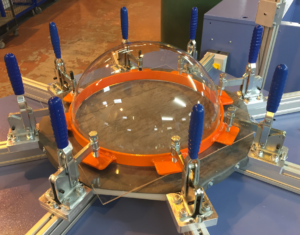

Q: What is dome blowing?

A: Dome blowing involves heating a plastic sheet and then forcing air pressure underneath it to create a dome shape. It’s used for skylights and light covers. And virtually any other dome-shaped products.

Q: What are the typical applications of dome blowing?

A: Dome blowing is commonly used for:

- Skylights

- Light diffusers

- Display domes

- Architectural features

Vacuum Forming:

Q: What is vacuum forming?

A: Vacuum forming involves heating a plastic sheet and then placing it over a mold. A vacuum is then applied to remove the air between the sheet and the mold, forcing the plastic to conform to the mold’s shape.

Q: What are the advantages of vacuum forming?

A: Vacuum forming is:

- Cost-effective for large production runs.

- Suitable for creating complex shapes.

- Relatively fast process.

Q: What are the limitations of vacuum forming?

A: Vacuum forming is suited for products with shallow draws. Deep draws can result in thinning of the plastic.

Drape Forming:

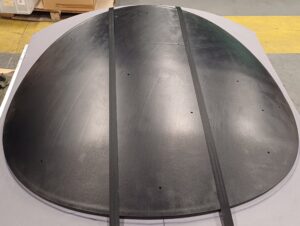

Q: What is drape forming?

A: Drape forming involves heating a plastic sheet and then draping it over a male mold. Gravity shapes the plastic. Pressure is also sometimes used.

Q: When is drape forming used?

A: Drape forming is used for large parts or parts with complex curves. Often in products where vacuum forming might be challenging. It’s also used when only a male mold is available.

Q: What are the differences between vacuum forming and drape forming?

A: The key difference is the use of a vacuum. Vacuum forming uses a vacuum to draw the plastic onto the mold, while drape forming relies on gravity and sometimes minimal pressure.

Choosing the Right Thermoforming Process:

Q: How do I choose the right thermoforming process for my project?

A: The best process depends on several factors:

- Part complexity: Simple bends suit line bending, while complex shapes may require vacuum or drape forming.

- Part size. Large parts are better for drape forming.

- Production volume. For large manufacturing runs, vacuum forming is preferred.

- Budget: Line bending is generally the most cost-effective for simple shapes.

Working with Ash Plastics:

Q: In summary, can Ash Plastics help me with my thermoforming project?

A: Yes! We have expertise in various thermoforming techniques and can help you choose the best process for your needs. Contact us to discuss your project requirements, and we’ll be happy to provide a consultation and quote. You can find out more about us here.

Q: What information should I provide when requesting a quote?

A: To get an accurate quote, please provide:

- Drawings or CAD files of the part.

- Dimensions of the part.

- Material specifications (type of plastic, thickness).

- Desired quantity.

We hope this FAQ has been informative. If you have any further questions about thermoforming, please don’t hesitate to contact us. We are experts in plastics and we are here to help!